Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

An overview of aluminum production processes and their associated co2 emissions. It also covers various co2 capture methods, including membrane separation, adsorption, and chemical absorption, and discusses their energy usage and efficiency. Data on co2 emissions from different sources and the percentage of us emissions, as well as typical pressures and capture methods for each source.

Typology: Study notes

1 / 37

This page cannot be seen from the preview

Don't miss anything!

Transport32%^ CommercialInd - ElecIndustrial11%19%

4% Residential6%^

Resid - Elec14% Comm - Elec14%

In Million Metric Tons of Carbon EquivalentIndustrial – Non-Electricity / Non-Steam Cement Production^

Ammonia Synthesis

Lime Production & Use

CO2 from natural Gas

Hydrogen Production

Aluminum Production

Soda Ash Production & Use

Ethylene Oxide^

Other Chemical Processes

from S. Barnicki (Eastman)

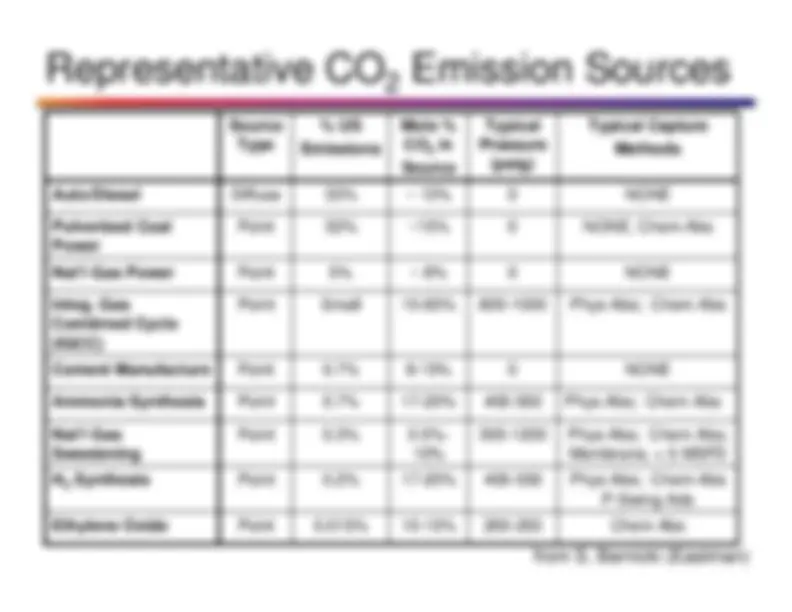

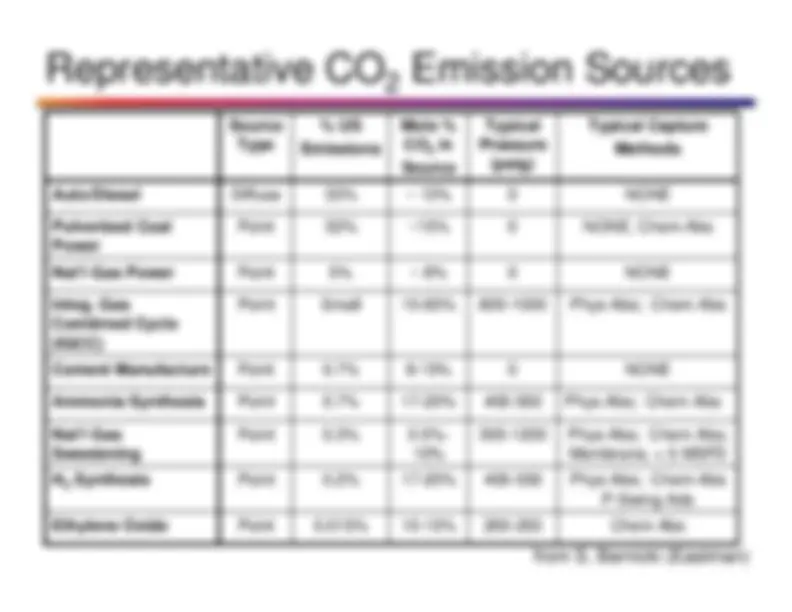

Source^ % USType^ Emissions

Mole %^ TypicalCO^ inPressure^2 (psig)^ Source

Typical Capture^ Methods

Auto/Diesel^

Diffuse^ 33%

~ 13%^

0

NONE

Pulverized CoalPower

Point^ 32%

~15%^

0 NONE, Chem Abs

Nat’l Gas Power

Point^

5%^ ~ 8%

0

NONE

Integ. GasCombined Cycle(IGCC)

Point^ Small

15-65%^

800-1000^ Phys Abs; Chem Abs

Cement Manufacture

Point^

0.7%^ 9-15%

0

NONE

Ammonia Synthesis

Point^

0.7%^ 17-20%

400-550^ Phys Abs; Chem Abs

Nat’l GasSweetening

Point^ 0.3%

0.5%-10%

300-1200^ Phys Abs; Chem Abs;Membrane, < 5 MSFD

H^ Synthesis^2

Point^ 0.2%

17-20%^

400-550^ Phys Abs; Chem Abs

P-Swing Ads

Ethylene Oxide

Point^

0.015%^ 10-15%

200-^

Chem Abs from S. Barnicki (Eastman)

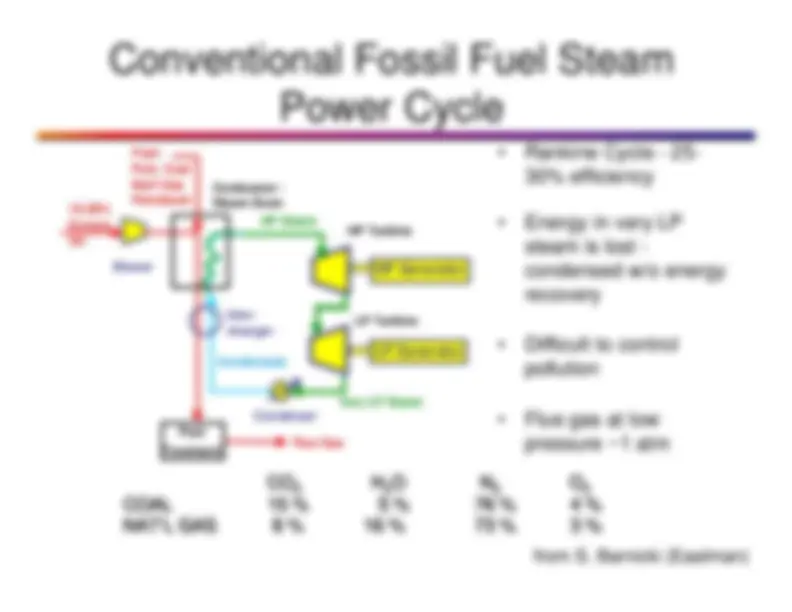

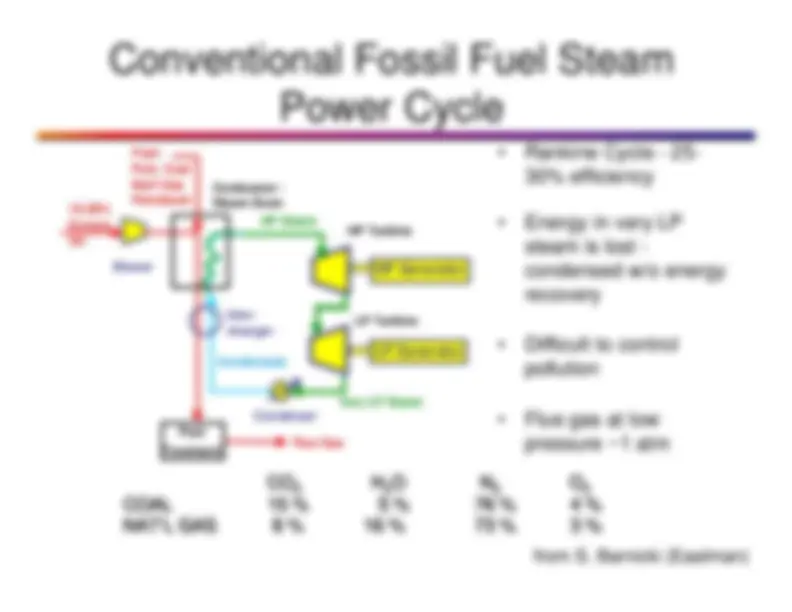

-^ Rankine Cycle - 25-30% efficiency•^ Energy in very LPsteam is lost -condensed w/o energyrecovery•^ Difficult to controlpollution•^ Flue gas at lowpressure ~1 atm HP SteamHP Turbine^ Very LP Steam Combustor /Steam Drum

HP Generator LP Turbine LP Generator Fuel:Pulv. CoalNat'l GasPetroleum Inter-changer^ CondensateCondenser^ PostTreatment 10-20%ExcessAir

Flue Gas Blower

3 %from S. Barnicki (Eastman)

Conventional Methods for CO

Capture (^2) membrane

from S. Barnicki (Eastman)

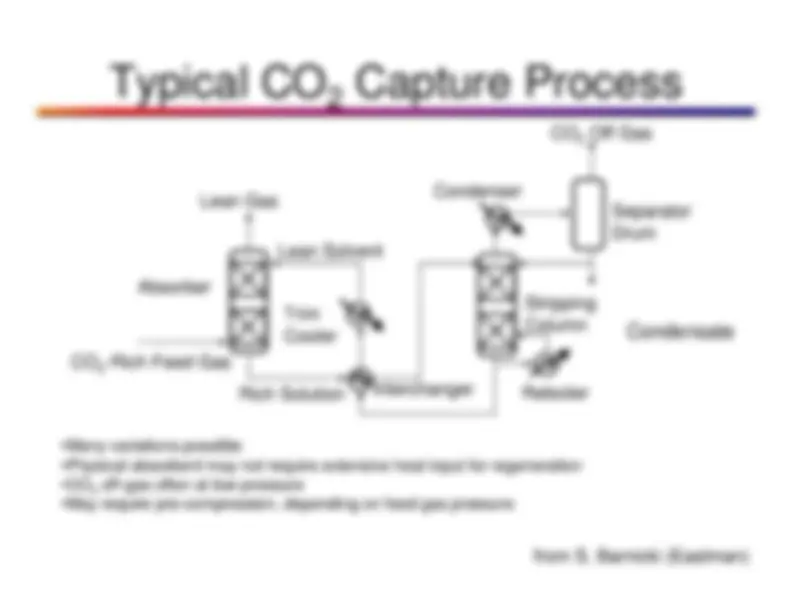

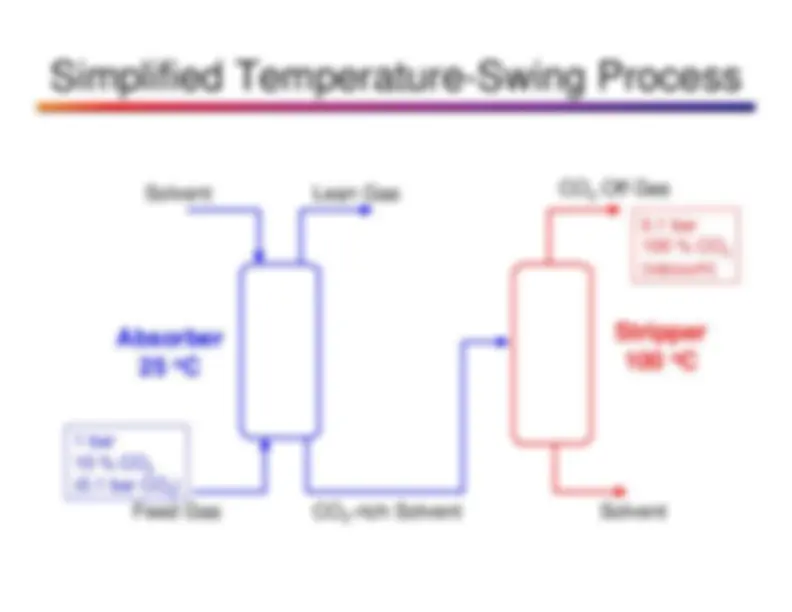

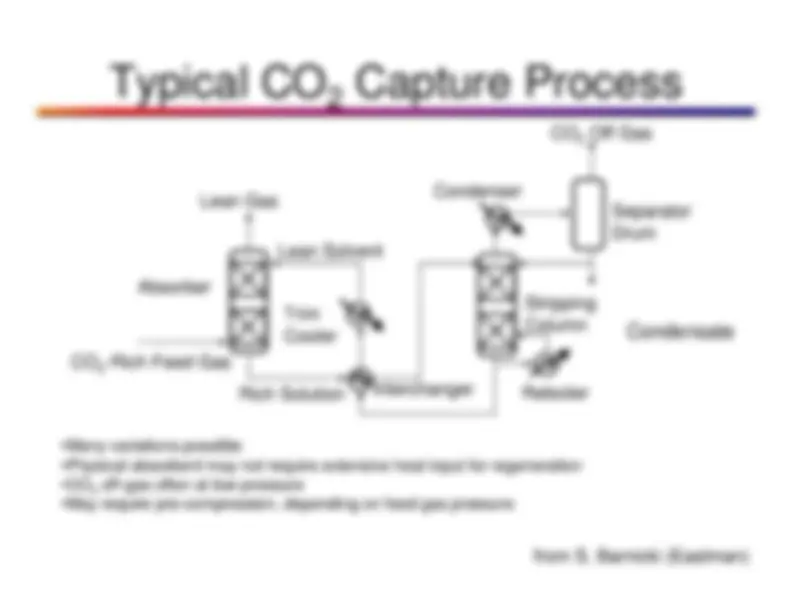

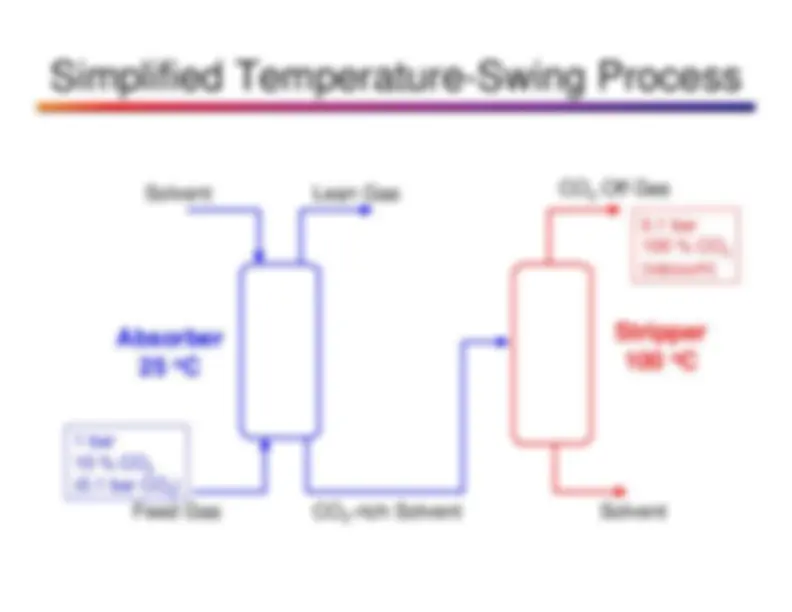

Lean Gas

COOff Gas^2 CondenserSeparatorDrum StrippingColumn Reboiler

Absorber

TrimCoolerInterchanger Lean Solvent Rich Solution CO-Rich Feed Gas^2 •Many variations possible •Physical absorbent may not require extensive heat input for regeneration •CO^ off-gas often at low pressure^2 •May require pre-compression, depending on feed gas pressure

from S. Barnicki (Eastman)

-^ Chemical reaction of absorbed CO

with solvent 2

-^ Typical absorbents:^ – Primary, secondary, tertiary, hindered amines^ •^ MEA, DEA, MDEA, TEA, 2-AMP^ – Alkali metal hydroxides or carbonates^ •^ NaOH, K

CO, Na^ CO 23 23

-^ 1st, 2nd amines limited ~0.5 mol CO

/mol Amine 2

-^ Tert & hindered can reach ~1.0 mol/mol •^ Regeneration by

∆T & often

∆^ P

-^ Solution concentration limited by solubility, corrosionand/or reactivity with O

, contaminants 2

from S. Barnicki (Eastman)

CO^2

-^ Can reach very low outlet P

CO^2

CO^2

-^ Loading proportional to P

CO^2

-^ Cannot reach very low outletPi.e., usually 0.1-2%, butCO^2 some can reach ppm levels MeOH, 0°C^ MeOH, 0°C20wt% DEA, 50 °C20wt% DEA, 50 °C above Liquid, atm CO2 P CO, vol/vol absorbent^2

from S. Barnicki (Eastman)

-^ Reacts with CO

to form carbamate complex 2

-^ Many commercially available processes •^ Choice dictated by removal requirements, stability tostream components •^ Generally can be selective between for H

S / CO 22

-^ Good for

P ~ 0.1 psi or higher CO^2

-^ Susceptible to O

degradation, other contaminants – 2 can be controlled • Good stage efficiencies

from S. Barnicki (Eastman)

-^ Basic idea similar for many akali- & alkali earth hydroxides &carbonates •^ Choice dictated by cost & solubility in water •^ Non-selective between H

S / CO 2 2

-^ Very best for

P^ above ~ 10 psi, but can work at lower P CO^2

CO^2

-^ Vacuum stripping for CO

removal to less than ~ 1000 ppm 2

-^ Poor stage efficiencies – tall absorption towers •^ Improved with amine as catalyst

from S. Barnicki (Eastman)

2-AMP(hindered)MEA (Prim)

(tert)MDEADEA (sec) TEA (tert)2NaHCO3Na2CO3 to

MeOH2KCO3K2CO3 to(Physical)

2-AMP(hindered)MEA (Prim)

(tert)MDEADEA (sec) TEA (tert)2NaHCO3Na2CO3 to

2KCO3MeOHK2CO3 to(Physical)

(^22) (Kcal/gmole CO(Kcal/gmole COHeat of Reaction Heat of Reaction

from S. Barnicki (Eastman)

-^ Primary Amines

-^ Secondary Amines

-^ Tertiary Amines

-^ Hindered Amines

-^ Mixed Amines

-^ Hot Potassium Carbonate

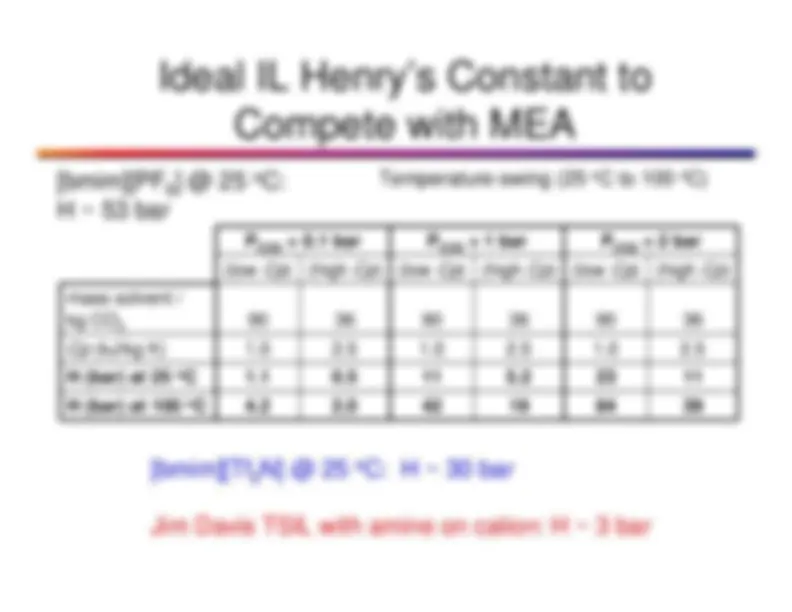

-^ Ionic Liquids

from S. Barnicki (Eastman)

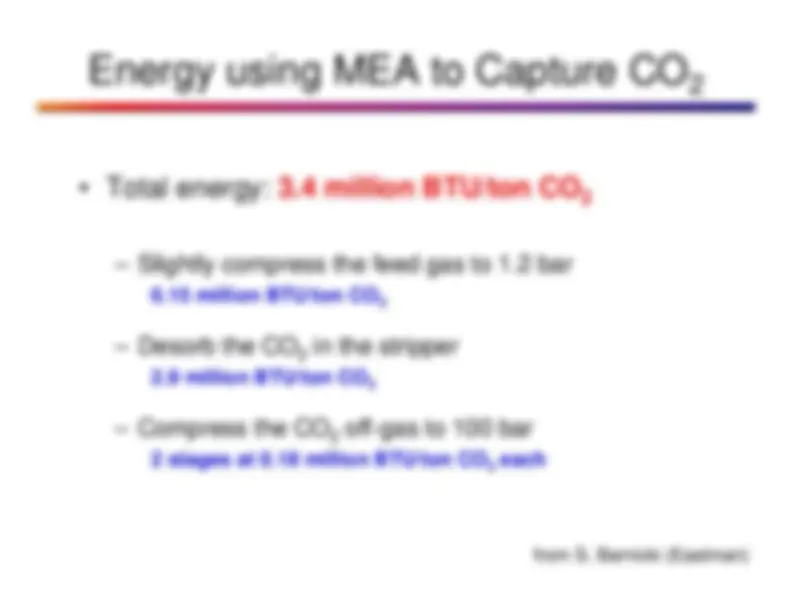

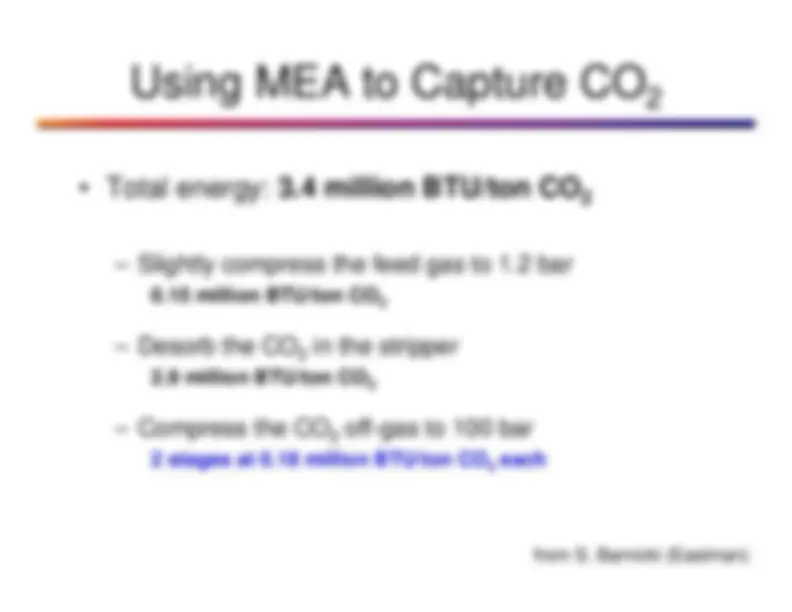

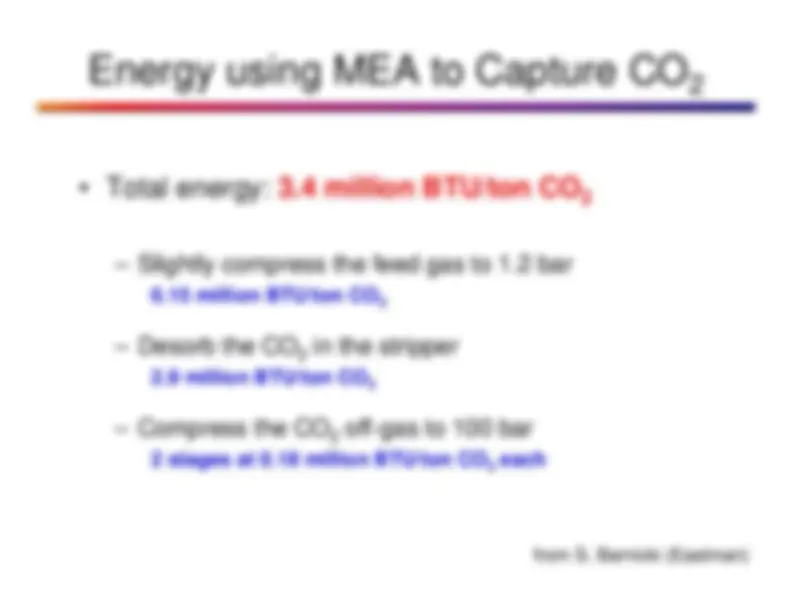

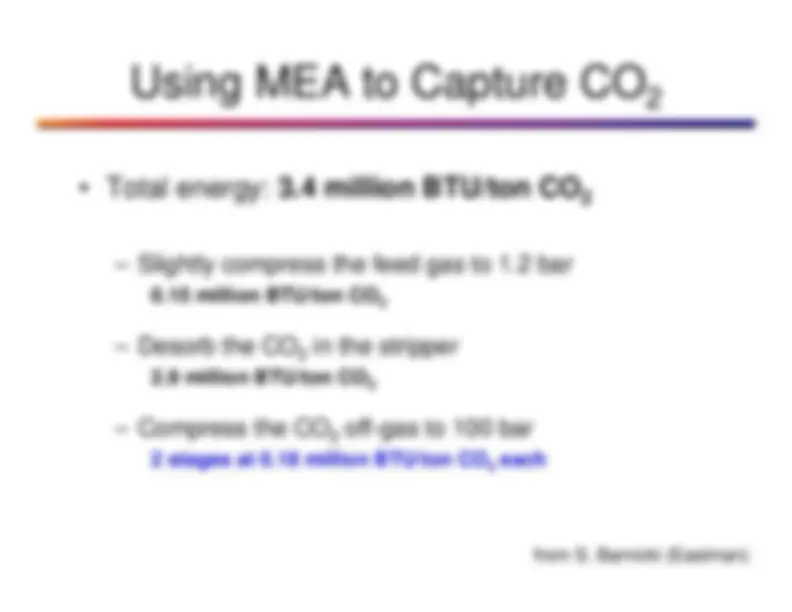

in flue gas 2

-^ Pre-compression of flue gas to overcome pressuredrop in absorber (14.7 psia to 18 psia) •^ Post-compression of recovered CO

to 10 and 100 2

atm in two stages, w/ interstage cooling

from S. Barnicki (Eastman)

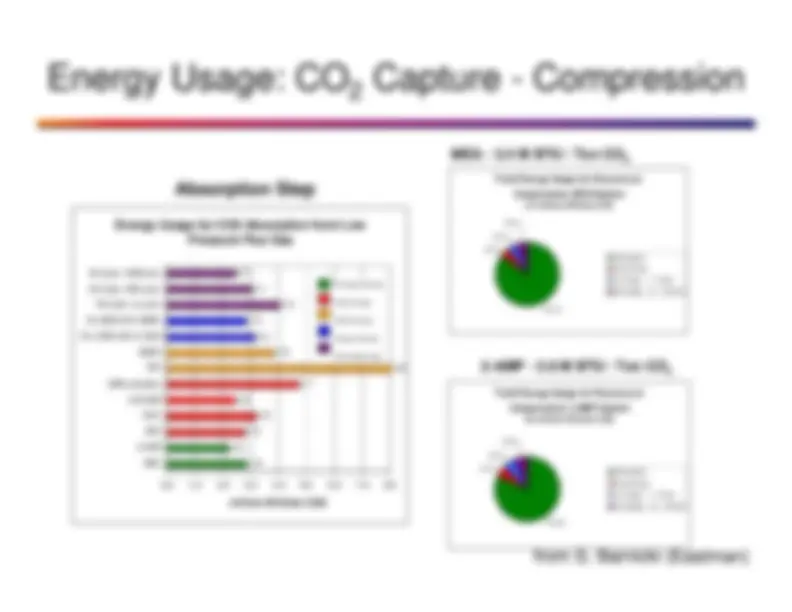

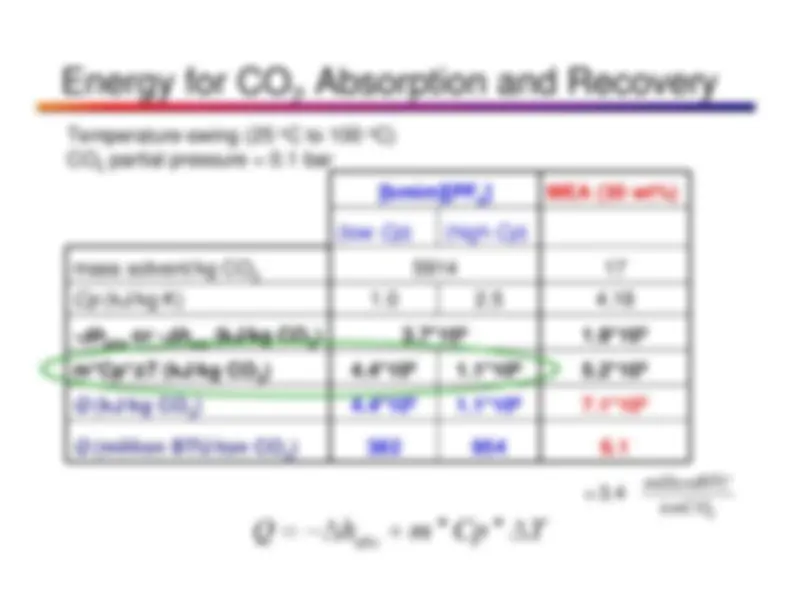

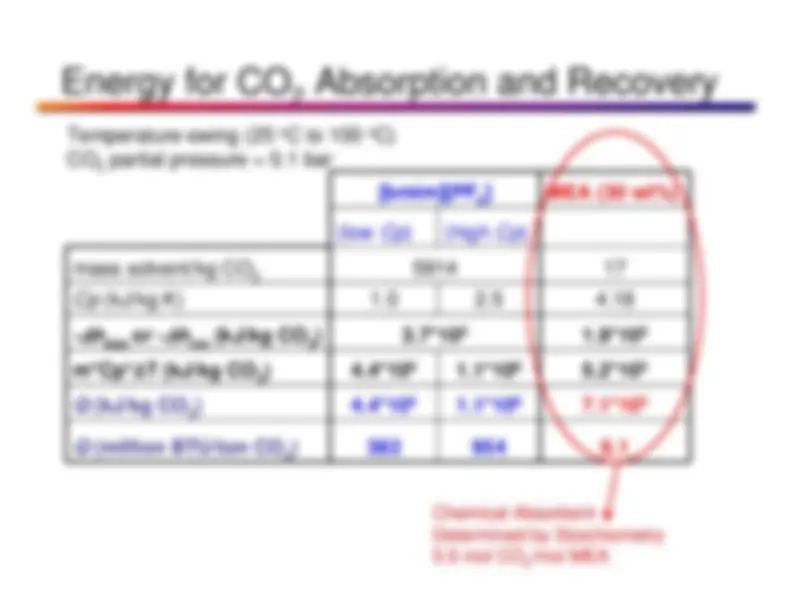

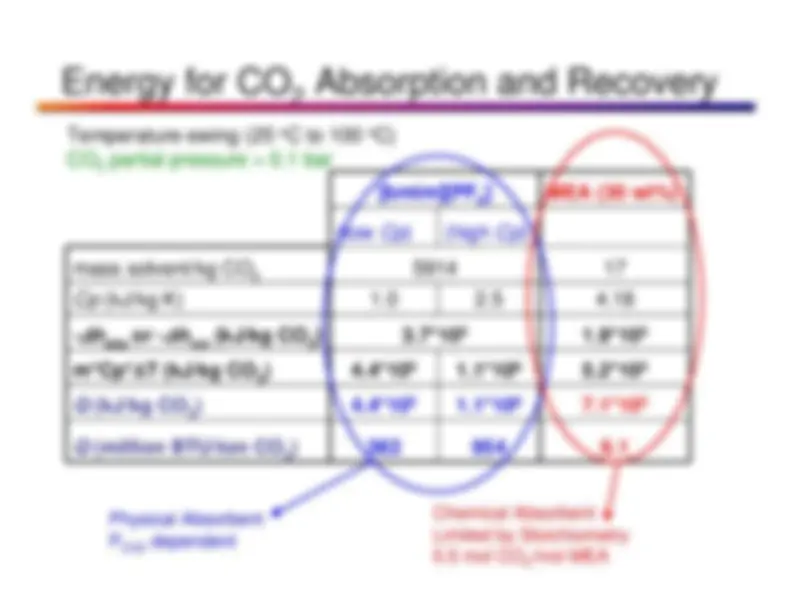

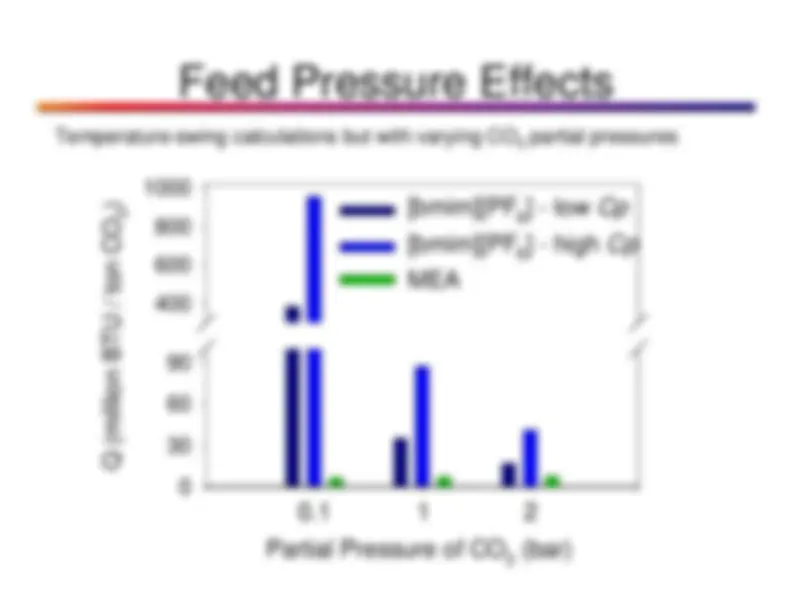

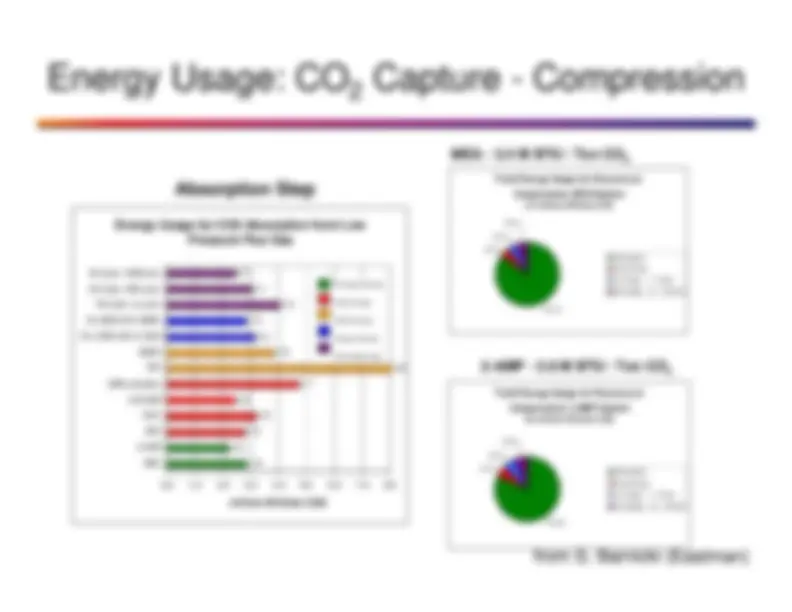

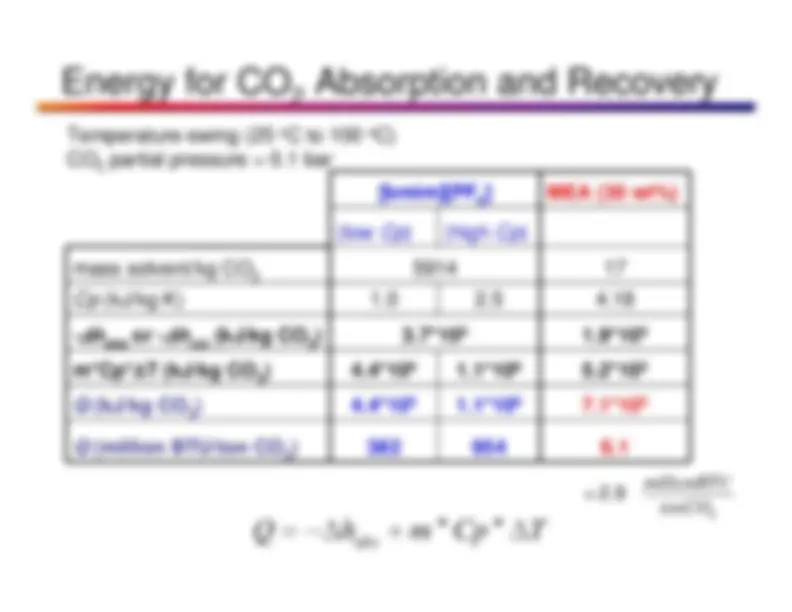

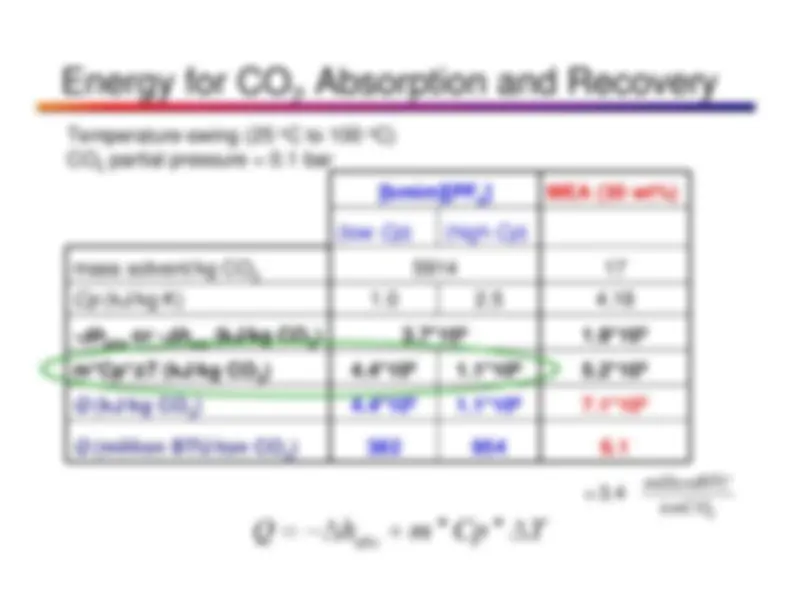

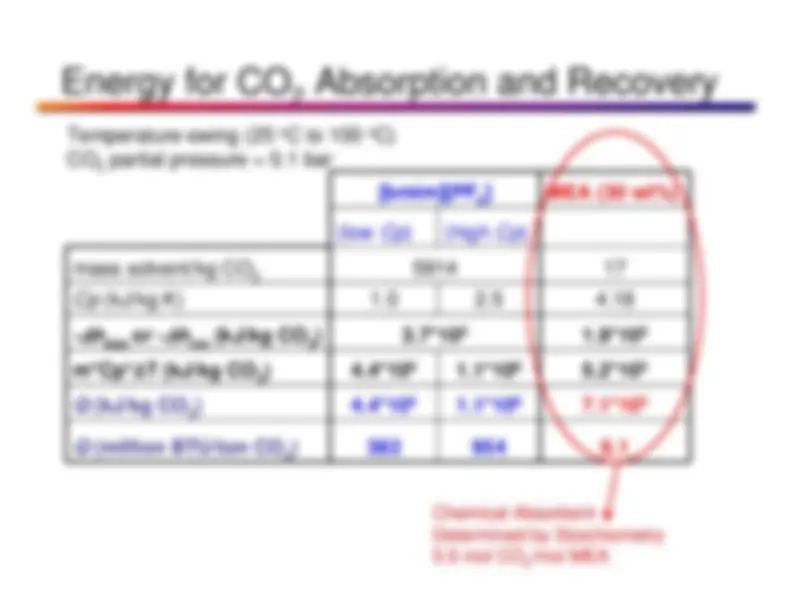

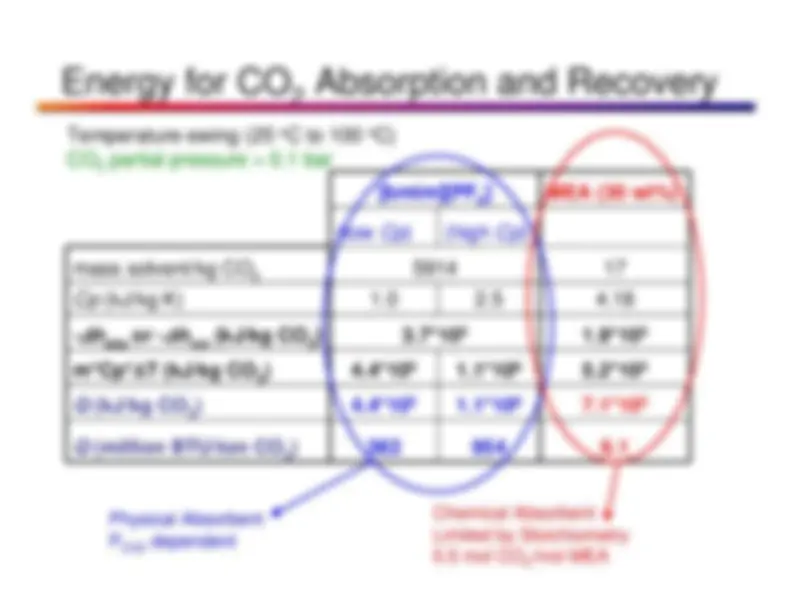

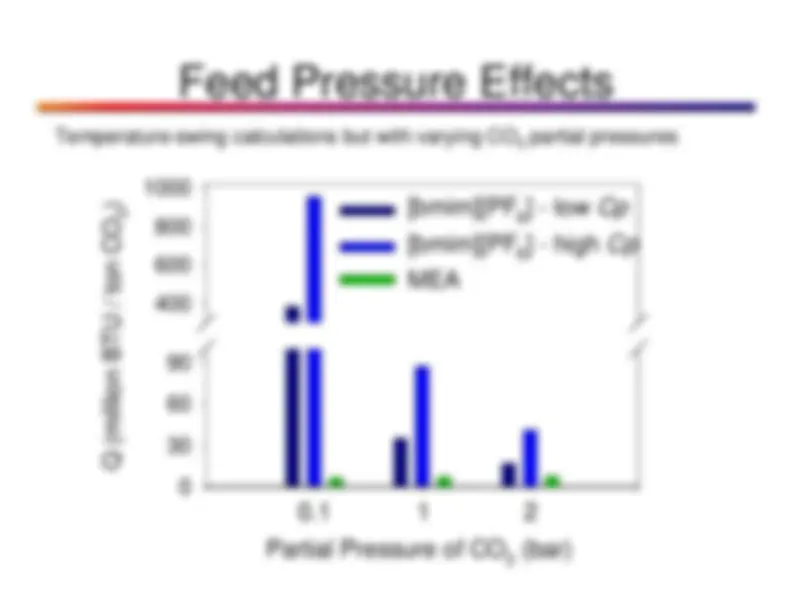

Energy Usage: CO

Capture - Compression 2^ MEA - 3.4 M BTU / Ton CO

2 Total Energy Usage for Recovery &Compression: MEA System3.4 million BTU/ton CO2 5.2%5.2%4.5%^ 85.1%

Absorption Feed Compr 1st stage - 1- 10 atm 2nd stage - 10 - 100 atm

Energy Usage for CO2 Absorption from LowPressure Flue Gas

4.7 2.5 3.2 2.8 2.3 2.

2.5^ 3.1^ 4.0^ 2.9^ 3.2^ 3. 0.0^ 1.0^ 2.0^ 3.0^ 4.

5.0^ 6.0^ 7.0^ 8. Pot Carb- AMP activPot Carb- DEA activPot Carb- no activ6% MEA/24% MDEA3% 2-MPz/30% 2-BAEMDEATEADIPA/sulfolane2-iPrAMPDGADEA2-AMPMEA^ million BTU/ton CO

P rimary A mines2nd A minesTert A minesM ixed A minesP o t Carbo nate Absorption Step

Total Energy Usage for Recovery &Compression: 2-AMP System2.8 million BTU/ton CO2 6.3%6.3%5.5%^ 81.8%

Absorption Feed Compr 1st stage - 1- 10 atm 2nd stage - 10 - 100 atm 2-AMP - 2.8 M BTU / Ton CO

2 from S. Barnicki (Eastman)